Home > Products > Woven Wire Mesh Weaving Types

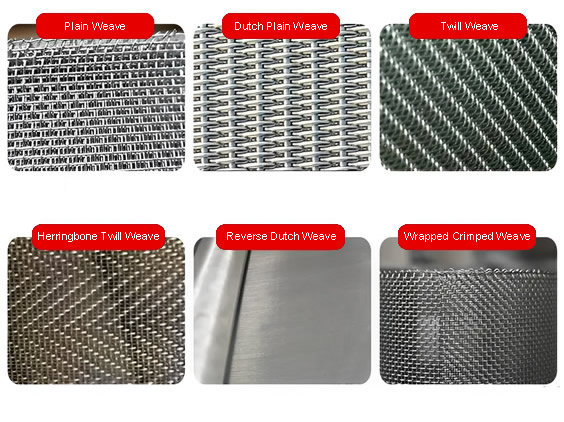

Woven Wire Mesh Patterns: Plain, Twill, Dutch Plain, Dutch Twilled, Reverse Dutch, Herringbone Twill, and Wrapped Crimped Weaves

Wetter Stainless Steel Wire Mesh Factory is a leading manufacturer and exporter of stainless-steel wire mesh. We offer a comprehensive selection designed to meet the diverse needs of various industries.

Woven wire mesh is a versatile material formed by systematically interlacing metal wires. Commonly fabricated from stainless steel, copper, aluminum, or brass, its characteristics are defined by its weave pattern, wire diameter, and aperture size.

Materials

- Stainless Steel: Offers exceptional durability and corrosion resistance, making it suitable for industrial and architectural applications.

- Copper: Known for its excellent thermal and electrical conductivity, copper is often used in decorative elements and electromagnetic shielding.

- Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for applications in the aeronautical and automotive industries.

- Brass: An alloy of copper and zinc, brass is valued for its acoustic properties and is frequently used in decorative applications.

Common Sizes

- Mesh Count: 2 mesh (coarse) to 400 mesh (fine)

- Aperture Sizes: 10 mm (2 mesh) to 0.037 mm (37 microns)

- Standard Sizes: Widths: 0.914 m, 1.0 m, 1.22 m, 1.5 m; Lengths: 15 m, 30 m, 50 m (custom dimensions available)

Customization

- Mesh Count: 37 mesh, 325 mesh (custom)

- Wire Diameter: 0.4 mm, 0.025 mm (custom)

- Aperture Size: Micrometer precision (custom)

- Material: Stainless steel (304, 316, 316L, 904L), Monel, Inconel, Hastelloy

- Weave Pattern: Plain, twill, Dutch twill

- Dimensions: Custom widths and lengths

- Edge Finishing: Welded, bound, cut

- Fabrication: Discs, cylinders, rolls,sheet,panel

- Perforations: Specified diameters and spacing

- Embossing: Patterns and depths

Typical Weaving Patterns

Plain Weave: This fundamental and versatile pattern features warp wires running parallel to the mesh length and weft wires crossing them perpendicularly. This creates square or rectangular openings, making it suitable for various applications.

- Applications: Filters, colanders, screening, shielding, mosquito nets

- Wire Materials: Stainless steel (AISI 304, 304L, 316, 316L, etc.), special steel (Cromax, Inconel, etc.), carbon steel, low carbon steel, galvanized steel, brass, bronze, copper, aluminum alloy

- Product Features: High filtration efficiency, low pressure loss, consistent mesh opening, dimensional stability, high open area, fire resistance.

Standard Sizes: Roll width (1m or 48"), roll length (30m or 100'), mesh sizes (2 to 400 mesh)

Twill Weave: In this pattern, each weft wire crosses over two warp wires, resulting in a robust and stable mesh fabric. This technique enhances strength and makes it ideal for heavy-duty applications.

- Applications: Similar to plain weave, but suitable for demanding environments

- Wire Materials: Stainless steel (AISI 304, 304L, etc.), carbon steel, galvanized steel, aluminum alloy, brass, phosphor bronze

Dutch Plain Weave: This weave employs a thicker warp wire compared to the weft, creating a strong and efficient filtering mesh. Filtration occurs through triangular passages, improving its effectiveness.

- Applications: Primarily used for filtration

Dutch Twilled Weave: This pattern features a thicker weft wire and a higher number of warp wires, resulting in smaller mesh openings. This design offers excellent filtration capabilities and dimensional stability, making it suitable for high-pressure environments.

- Applications: Filtration across various industries

- Wire Materials: Stainless steel (AISI 304, 304L, etc.), steel alloy, aluminum alloy, carbon steel, brass, copper, phosphor bronze

- Product Features: High-pressure filtration, strong dimensional properties, fire resistance, corrosion resistance

Reverse Dutch Weave: This weave features closely spaced warp wires and thicker, more spaced weft wires. This design enhances filtration efficiency and is ideal for high-precision applications in industries like pharmaceuticals, food, and chemicals.

- Wire Materials: Stainless steel (AISI 304, 304L, etc.), special steel alloy, galvanized steel, carbon steel, brass, aluminum alloy, copper

- Features: High-pressure filtration, excellent dimensional strength, corrosion resistance, fire resistance

Herringbone Twill Weave: Herringbone twill is a decorative variation where the diagonal twill reverses direction at regular intervals, creating a zigzag pattern. While less common in industrial applications, this pattern is used in architectural and design contexts for its aesthetic appeal while still providing structural integrity and functionality. The wire diameters and mesh counts for herringbone twill can be adjusted to match specific structural and visual requirements.

Specifications

- Weave Pattern: Herringbone twill

- Material: Stainless steel, copper, aluminum, brass

- Wire Diameter: Customizable

- Mesh Count: Customizable

- Width: 1000 mm to 2000 mm (39.37 inches to 78.74 inches)

- Length: 1000 mm to 3000 mm (39.37 inches to 118.11 inches)

- Open Area: 10% to 60%

- Surface Finish: Mill finish, brushed, polished

Benefits

- Aesthetic appeal: Visually striking pattern

- Structural integrity: Strong and durable

- Versatility: Customizable to meet specific needs

Applications

- Architectural design: Facades, balustrades, decorative elements

- Interior design: Furniture, partitions, wall coverings

- Security: Fencing, enclosures

- Industrial filtration: Fine particle filtration

- Decorative elements: Art installations, sculptures

Wrapped Crimped Weave: The wrapped crimped weave type woven wire mesh is an advanced variation of the traditional crimped wire mesh, distinguished by its unique method of crimping and weaving the wires, which enhances the overall stability and aesthetic appeal of the mesh. This type of mesh features wires that are pre-crimped before weaving, creating a secure and intricate pattern that holds its shape under stress and strain.

Characteristics

- Unique weaving process: Pre-crimped wires woven together

- Enhanced stability: Secure, intricate pattern

- Durability: Crimps absorb energy, distribute stress

Specifications

- Wire Diameter: 0.5 mm to 10 mm

- Aperture Size: 2 mm to 100 mm

- Mesh Count: Typically lower than traditional crimped wire mesh

Applications

- Architectural Panels

- Vibrating Screens

- Fencing and Enclosures

- Decorative Features

Customization

- Edge Treatments

- Surface Treatments

- Forming and Shaping

Services

Wetter Stainless Steel Wire Mesh Factory goes beyond standard offerings to provide tailored solutions. Our customization capabilities include:

- Mesh size and pattern adjustments: We can produce mesh according to your specific requirements, including custom sizes and weave patterns.

- Specialized materials: We offer a wide range of wire materials to suit unique applications, including special steel alloys for extreme environments.

- Precise roll dimensions: We can provide mesh rolls in precise dimensions to perfectly fit your project needs.

- Enhanced filtration and durability: We can customize mesh properties to improve filtration efficiency and durability for your specific application.

Our team is dedicated to delivering high-quality wire mesh solutions that meet the precise needs of various industries. Contact us today to discuss your specific requirements and find the perfect mesh solution for your project.