Home > Products > Five Layer Filter Cloth

Five Layer Stainless Steel Sintered Wire Mesh Filter Cloth

Five layer stainless steel sintered wire mesh filter cloth stands out as a premium filtering solution renowned for its exceptional performance and versatility. five layer stainless steel sintered wire mesh filter cloth offers a compelling combination of strength, durability, and versatility. Its exceptional properties and wide range of applications make it a valuable asset in numerous filtering tasks across various industries.

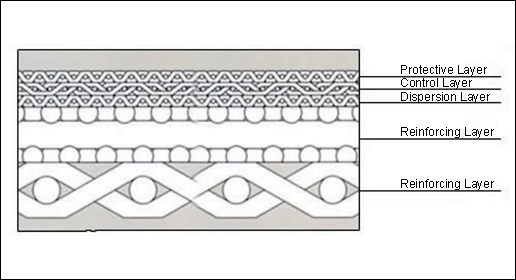

Construction

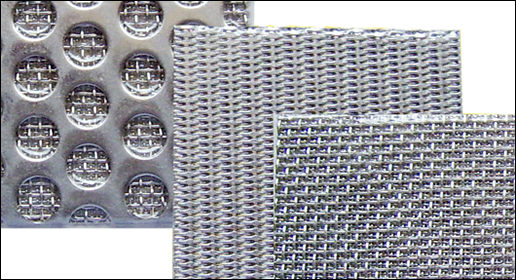

- Sintered Structure: Unlike standard woven mesh, the five layers of stainless steel mesh are fused through a sintering process, creating a robust laminate structure. This eliminates the need for additional internal support, enhancing overall strength and durability.

- Multi-Layered Advantage: Compared to 3-layer options, the five-layer construction offers a finer filtering degree and potentially improved strength and stability.

Properties

- Enhanced Strength: The sintered structure provides superior strength, allowing for the creation of filter elements without internal support.

- Durability and Easy Maintenance: This filter cloth boasts a long lifespan and can be repeatedly cleaned, minimizing replacement needs.

- Corrosion Resistance: The 304 stainless steel construction offers excellent resistance to corrosion, making it suitable for various environments.

- Surpasses Alternatives: Sintered wire mesh surpasses sintered metal powder and porcelain filter media in terms of its comprehensive properties.

Applications

Five layer stainless steel sintered wire mesh filter cloth finds application in a wide range of filtering tasks, including:

- Chemical Processing: Effective filtration of various materials like polyester, oil, and sulfur in chemical products.

- Water and Air Purification: Plays a crucial role in filtering pure water and air, ensuring cleanliness and quality.

Technical Specifications

Material Options

- Type 304 Stainless Steel: Known for good corrosion resistance and strength.

- Type 316 and 316L Stainless Steel: These types provide excellent corrosion resistance, with Type 316L having lower carbon content for better welding corrosion resistance.

- Duplex Stainless Steel: Offers a combination of increased strength and corrosion resistance.

- Hastelloy: Best suited for the most severe environments, offering the highest level of corrosion resistance.

Wire Diameter and Mesh Properties

- Range: From 0.004 inches (0.10 mm) to 0.020 inches (0.50 mm).

- Porosity and Strength: Smaller wire diameters lead to higher porosity, which is ideal for finer filtration, whereas larger diameters enhance the mesh's overall strength.

Mesh Count and Filtration Capabilities

- Range: Typically from 100 to 400 mesh.

- 100 Mesh: Provides coarser filtration, suitable for larger particulate separation.

- 400 Mesh: Ensures very fine filtration, effective in capturing smaller particles.

Pore Size and Thickness

- Pore Size: Ranges from a few microns to several hundred microns, tailored to specific filtration requirements.

- Thickness: Varies from 1/16 inch (1.6 mm) to 1/4 inch (6.4 mm), where thinner meshes are suited for lower pressure applications and thicker meshes for high-pressure environments.

Filtration Performance

- Filtration Fineness: Ranging from 2 to 60 microns, this mesh can handle diverse filtering needs from coarse to very fine particles.

- Operational Temperature Range: Effective from -20°C to 600°C, accommodating a wide spectrum of temperature conditions.

- Maximum Pressure Drop: Capable of withstanding up to 3.2 MPa, suitable for significant pressure differentials during filtration processes.

Standard Dimensions

- Width: 500 mm (19.6 inches).

- Length: 1000 mm (39.3 inches), available in large sheets to meet various application needs.

- Number of Layers: Options range from 2 to 6 layers, allowing for optimal customization based on specific filtration requirements; however, five layers are most commonly used due to their balanced filtration efficiency.