Home > Products > Metal Sheet Mesh

Metal Sheet Mesh, Exapnded Metal mesh sheet,Perforated metal sheet mesh

Metal sheet mesh offers a versatile solution for a wide range of industrial and architectural applications. Featuring high durability, excellent strength-to-weight ratio, and resistance to corrosion, metal sheet mesh is ideal for use in filtration, ventilation, safety guards, and decorative elements. Its precise manufacturing allows for customization in terms of size, shape, and material, catering to specific needs such as load-bearing capabilities and aesthetic requirements. The open area of the mesh ensures efficient airflow and visibility while maintaining structural integrity, making it a valuable component in both functional and design-oriented projects.

Material

Metal sheet mesh is available in various materials to suit different applications. Common materials include:

- 304 Stainless Steel: Known for its excellent corrosion resistance and strength.

- 316 Stainless Steel: Offers enhanced corrosion resistance, particularly against chlorides and other industrial solvents.

- Aluminum: Lightweight and resistant to corrosion, ideal for decorative and lightweight structural applications.

- Brass: Known for its decorative appeal and good corrosion resistance.

- Copper: Provides excellent electrical conductivity and corrosion resistance.

- Nickel: Highly resistant to corrosion and oxidation, suitable for harsh environments.

Mesh Count

Mesh count refers to the number of openings per linear inch. Common mesh counts for metal sheet mesh include:

- Small Mesh: 12.5 mm (0.5 inches) to 20 mm (0.79 inches) opening sizes, ideal for fine filtration and small-scale applications.

- Medium Mesh: 20 mm (0.79 inches) to 50 mm (1.97 inches) opening sizes, used in fencing and protective barriers.

- Heavy Mesh: 50 mm (1.97 inches) to 200 mm (7.87 inches) opening sizes, suitable for heavy-duty applications such as walkways and platforms.

Welding

Welding is used to join wires at intersections for added strength, commonly seen in:

- Welded Wire Mesh: Produced by welding intersecting wires, creating a strong and rigid structure ideal for fencing and security applications.

Punching

Punching creates holes in a metal sheet to form:

- Perforated Metal Sheet: Made by punching various shapes of holes into the metal sheet, used for filtration, soundproofing, and decorative purposes.

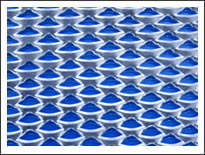

Expanding

Expanding stretches the metal sheet to create openings:

Expanded Metal Mesh: Formed by stretching a metal sheet to create diamond-shaped openings, providing high strength and rigidity while allowing for airflow and visibility.

Standard Shapes

Standard shapes of metal sheet mesh include:

- Diamond: The most common shape, offering a balance of strength and open area.

- Hexagonal: Provides a unique appearance and slightly different mechanical properties.

- Special Shapes: Custom shapes tailored to specific applications.

Finishing

Finishing processes enhance the durability and appearance of metal sheet mesh:

- Galvanizing: Coating with zinc to improve corrosion resistance.

- Painting or Powder Coating: Adding a protective and decorative layer of paint or powder.

- Anodizing: Primarily for aluminum, increasing corrosion resistance and surface hardness.

Typical Standards

Metal sheet mesh adheres to various industry standards, ensuring quality and consistency:

ASTM (American Society for Testing and Materials): Standards for material quality and mechanical properties.

BS (British Standards): UK standards for material and product specifications.

Packaging

Metal sheet mesh is typically packaged to ensure safe transport and storage:

- Rolls: Smaller mesh sizes are often rolled for convenience.

- Sheets: Larger and heavier meshes are stacked in flat sheets.

- Pallets: Bulk packaging for industrial quantities, often shrink-wrapped and strapped to pallets for stability.

| Specification of Expanded Metal Mesh | ||||||

| Sheet Thickness | Opening in Width |

Opening in Length |

Stem |

Roll Width mm |

Roll Length mm |

Weight kg/m2 |

| 0.5 | 2.5 | 4.5 | 0.5 | 0.5 | 1 | 1.8 |

| 0.5 | 10 | 25 | 0.5 | 0.6 | 2 | 0.73 |

| 0.6 | 10 | 25 | 1 | 0.6 | 2 | 1 |

| 0.8 | 10 | 25 | 1 | 0.6 | 2 | 1.25 |

| 1 | 10 | 25 | 1.1 | 0.6 | 2 | 1.77 |

| 1 | 15 | 40 | 1.5 | 2 | 4 | 1.85 |

| 1.2 | 10 | 25 | 1.1 | 2 | 4 | 2.21 |

| 1.2 | 15 | 40 | 1.5 | 2 | 4 | 2.3 |

| 1.5 | 15 | 40 | 1.5 | 1.8 | 4 | 2.77 |

| 1.5 | 23 | 60 | 2.6 | 2 | 3.6 | 2.77 |

| 2 | 18 | 50 | 2.1 | 2 | 4 | 3.69 |

| 2 | 22 | 60 | 2.6 | 2 | 4 | 3.69 |

| 3 | 40 | 80 | 3.8 | 2 | 4 | 5.00 |

| 4 | 50 | 100 | 4 | 2 | 2 | 11.15 |

| 4.5 | 50 | 100 | 5 | 2 | 2.7 | 11.15 |

| 5 | 50 | 100 | 5 | 1.4 | 2.6 | 12.39 |

| 6 | 50 | 100 | 6 | 2 | 2.5 | 17.35 |

| 8 | 50 | 100 | 8 | 2 | 2.1 | 28.26 |