Home > Products > Filter Elements

Stainless Steel Wire Mesh Filter Elements

Wetter Stainless Steel Wire Mesh Factory supplies stainless steel filter elements in various sizes and filtration grades, catering to diverse industrial needs. Our product range includes two main filter media options: stainless steel sintered fiber web and stainless steel wire woven cloth. These filter elements are widely used in the petroleum, chemical, chemical fiber, pharmaceutical, wastewater treatment, and other industrial sectors.

Cylindrical Filter Elements

-

Features: Constructed from woven or sintered stainless steel mesh, offering uniform filtration and high mechanical strength.

-

Applications: Utilized in petrochemical industries, water treatment facilities, and food processing plants for efficient filtration of liquids and gases.

-

Specifications:

- Diameter: 25 mm, 50 mm, 75 mm, 100 mm

- Length: 100 mm, 200 mm, 300 mm, 400 mm

- Mesh Count: 10 mesh, 20 mesh, 50 mesh, 100 mesh

- Wire Diameter: 0.1 mm, 0.2 mm, 0.3 mm, 0.5 mm

- Open Area: 30%, 40%, 50%, 60%

- Filtration Rating: 10 microns, 20 microns, 50 microns, 100 microns

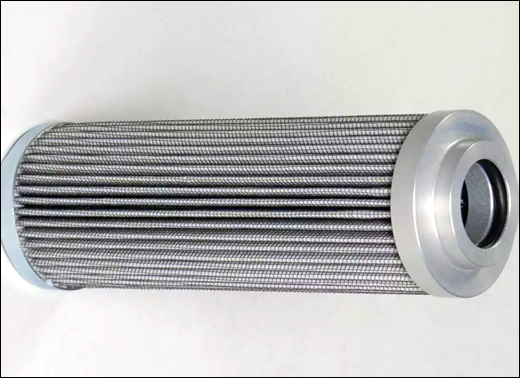

Pleated Filter Elements

-

Features: Designed with a pleated structure to increase surface area, enhancing filtration capacity without increasing overall size.

-

Applications: Ideal for hydraulic systems, oil filtration, and air purification processes requiring high efficiency in a compact form.

-

Specifications:

- Pleat Density: 10 pleats per inch, 20 pleats per inch

- Media Area: 1 square meter, 2 square meters

- Filtration Rating: 5 microns, 10 microns, 20 microns

- Pressure Drop: 0.1 bar, 0.2 bar, 0.5 bar

- Temperature Rating: 100°C, 200°C, 300°C

Sintered Mesh Filter Elements

-

Features: Composed of multiple layers of sintered wire mesh, providing a robust structure with precise filtration capabilities and excellent backwashing properties.

-

Applications: Used in oil and gas industries, chemical processing, and aerospace applications where high strength and temperature resistance are required.

-

Specifications:

- Pore Size: 5 microns, 10 microns, 20 microns, 50 microns

- Porosity: 30%, 40%, 50%, 60%

- Filtration Rating: 5 microns, 10 microns, 20 microns

- Pressure Rating: 50 psi, 100 psi, 200 psi

- Temperature Rating: 200°C, 300°C, 400°C

Cone-Shaped Filter Elements

-

Features: Feature a conical design allowing for directional flow filtration, reducing flow resistance and facilitating easy installation.

-

Applications: Commonly used in extruder screens, polymer filtration, and automotive exhaust systems to handle high flow rates and pressures.

-

Specifications:

- Cone Angle: 30 degrees, 45 degrees, 60 degrees

- Diameter: 50 mm, 100 mm, 150 mm

- Length: 100 mm, 200 mm, 300 mm

- Mesh Count: 20 mesh, 50 mesh, 100 mesh

- Filtration Rating: 10 microns, 20 microns, 50 microns

Disc Filter Elements

-

Features: Flat, round filters made from stainless steel mesh, suitable for compact filtration solutions and easy system integration.

-

Applications: Employed in fluid and gas filtration, as well as protective screens for pumps and nozzles in various industries.

-

Specifications:

- Diameter: 50 mm, 100 mm, 150 mm, 200 mm

- Thickness: 5 mm, 10 mm, 15 mm

- Mesh Count: 10 mesh, 20 mesh, 50 mesh

- Wire Diameter: 0.1 mm, 0.2 mm, 0.3 mm

- Open Area: 30%, 40%, 50%

- Filtration Rating: 10 microns, 20 microns, 50 microns

Basket Filter Elements

-

Features: Cylindrical basket shape with a handle for easy removal and cleaning; designed for high capacity and durability.

-

Applications: Widely used in chemical and oil industries for pre-filtration and protection of pumps, valves, and other equipment from debris.

-

Specifications:

- Diameter: 100 mm, 150 mm, 200 mm

- Height: 100 mm, 150 mm, 200 mm

- Mesh Count: 20 mesh, 50 mesh, 100 mesh

- Wire Diameter: 0.3 mm, 0.5 mm, 1 mm

- Handle Type: Loop handle, straight handle

Capsule Filter Elements

-

Features: Enclosed in a capsule with welded seams to prevent leakage and contamination, suitable for sterile or critical applications.

-

Applications: Used in chemical processing, pharmaceutical manufacturing, and biotech industries for precise and contaminant-free filtration.

-

Specifications:

- Diameter: 25 mm, 50 mm, 75 mm

- Length: 50 mm, 100 mm, 150 mm

- Filtration Rating: 5 microns, 10 microns, 20 microns

- Pressure Rating: 50 psi, 100 psi, 150 psi

- Temperature Rating: 100°C, 200°C, 300°C

Layered Mesh Filter Elements

-

Features: Consist of multiple layers of woven wire mesh, allowing for graduated filtration and enhanced structural integrity.

-

Applications: Ideal for hydraulic systems, lubrication systems, and chemical processing where multi-stage filtration is required.

-

Specifications:

- Number of Layers: 2 layers, 3 layers, 4 layers, 5 layers

- Mesh Count (Per Layer): 100 mesh, 200 mesh, 300 mesh

- Filtration Rating: 5 microns, 10 microns, 20 microns

- Pressure Rating: 50 psi, 100 psi, 200 psi

Tube Filter Elements

-

Features: Tubular shape made from perforated or woven stainless steel mesh, suitable for high-flow filtration and easy installation in pipelines.

-

Applications: Used in water treatment, oil refining, and gas filtration processes.

-

Specifications:

- Diameter: 25 mm, 50 mm, 75 mm

- Length: 100 mm, 200 mm, 300 mm, 400 mm

- Mesh Count: 10 mesh, 20 mesh, 50 mesh

- Wire Diameter: 0.2 mm, 0.3 mm, 0.5 mm

- Filtration Rating: 10 microns, 20 microns, 50 microns

Hollow Filter Elements

-

Features: Designed with a hollow center to allow flow-through filtration, maximizing contact with the filter media and reducing pressure drop.

-

Applications: Commonly used in fuel filtration, oil filtration, and gas separation applications where efficient flow and filtration are critical.

-

Specifications:

- Diameter: 50 mm, 100 mm, 150 mm

- Length: 100 mm, 200 mm, 300 mm

- Filtration Rating: 10 microns, 20 microns, 50 microns

- Pressure Rating: 50 psi, 100 psi, 150 psi

- Temperature Rating: 100°C, 200°C, 300°C

Stainless Steel Sintered Fiber Web

The stainless steel sintered fiber web is a high-performance filter media made from sintered stainless steel fibers. This material offers excellent filtration capabilities, including:

- High Porosity: Provides a low-pressure drop and high flow rate.

- Thermal Stability: Capable of withstanding high temperatures without compromising filtration performance.

- Mechanical Strength: Durable and resistant to deformation under high pressure.

- Chemical Resistance: Resistant to corrosion from various chemicals, making it suitable for harsh environments.

Stainless Steel Wire Woven Cloth

The stainless steel wire woven cloth is a versatile and widely used filter media. It features:

- Uniform Weave: Ensures consistent and accurate filtration ratings.

High Dirt Holding Capacity: Captures and retains a significant amount of contaminants. - Easy Cleaning: Can be cleaned using conventional chemical methods for repeated use.

- Long Lifespan: Designed for extended service life with minimal maintenance.

Advantages of Stainless Steel Pleated Filter Elements - High Dirt Holding Capacity: Capable of capturing and retaining large amounts of contaminants, ensuring efficient filtration.

- Reliable Standard Specifications: Manufactured to meet consistent quality standards, providing dependable performance.

- Low Pressure Drop: High porosity allows fluids to pass through with minimal resistance, reducing energy consumption.

- Accurate Filtration Rating: Effectively captures particles of a specific size and larger, ensuring precise filtration.

- Easy Cleaning and Long Lifespan: Conveniently cleaned using conventional chemical methods, with an extended service life.

- Increased Filtration Area: The pleated design provides a larger surface area for capturing contaminants, enhancing filtration efficiency.

Common Specifications and Sizes

- Diameter: Standard diameters include 10mm, 25mm, 50mm, and 100mm. These sizes cater to different filtration system requirements, providing flexibility and adaptability for various industrial applications.

- Length: The lengths of these filter elements typically range from 50mm to 1000mm. This range allows for customization to fit specific system configurations and ensures optimal performance in different environments.

- Filtration Grades:Filtration grades are available from 1 micron to 100 microns. This wide range allows for precise control over the filtration process, ensuring that the filter elements can capture particles of various sizes as required by the application.

- Pressure Ratings:Pressure ratings of up to 300 bar ensure reliability in high-pressure environments. These robust ratings make our filter elements suitable for a wide range of industrial applications, providing consistent performance even under challenging conditions.

Wetter Stainless Steel Wire Mesh Factory ensures that our stainless steel wire mesh filter elements are tailored to meet the precise needs of our customers, providing efficient and reliable filtration solutions for various industrial applications.