Home > Products > Choose Stainless Steel Wire Mesh Grades

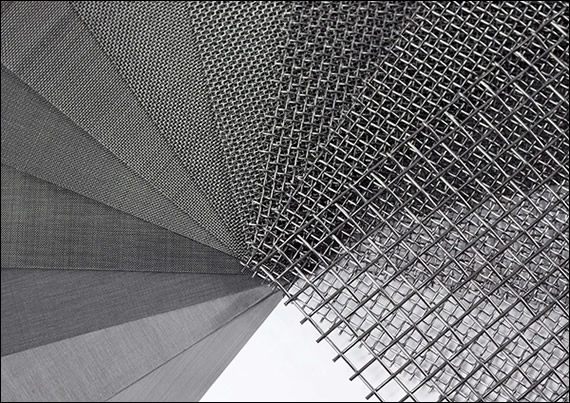

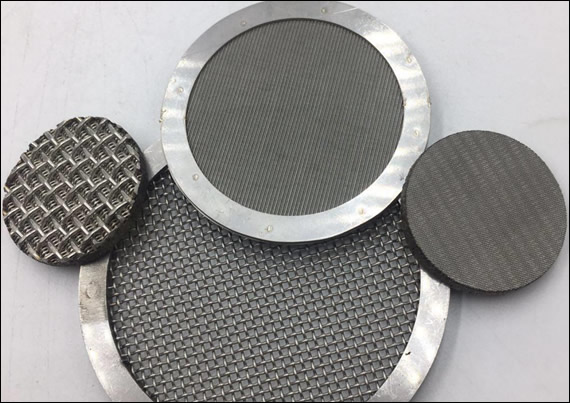

Different Grades of Stainless Steel Wire Mesh Made of Different Stainless Steel Materials

Wetter supplies stainless steel wire mesh processed from various grades of stainless steel material, mainly SUS304, 304L, 316 and 316L. Also 309, 310, 430 and 430L. Different grades of stainless steel has various properties and chemical composition as detail listed in the form below. The material decides the property of the finished stainless steel wire mesh products. Our customers can choose stainless steel material according to your demand and budget.

Factors to Consider:

- Environment: Consider the exposure conditions like temperature, humidity, and potential for corrosion.

- Application: Analyze the mesh's function, such as filtration, security, or aesthetics.

- Strength Requirements: Determine the level of strength and rigidity needed for the application.

- Budgetary Constraints: Be mindful of the cost variations between different stainless steel grades.

Common Stainless Steel Wire Mesh Materials:

- AISI 304 (SS304): The most widely used grade, offering good corrosion resistance and formability. Suitable for indoor environments, general filtration, and decorative applications.

- AISI 316 (SS316): Includes molybdenum for enhanced corrosion resistance in saltwater, harsh chemicals, or extreme temperatures. Ideal for marine, chemical processing, and high-temperature applications.

- AISI 304L (SS304L): Similar to 304 but with lower carbon content, improving weldability. A good choice for welded mesh projects requiring good corrosion resistance.

- AISI 316L (SS316L): Similar to 316 but with lower carbon content, enhancing weldability while maintaining excellent corrosion resistance in harsh environments.

- Special Alloys: For unique applications, specific alloys offer properties like high heat tolerance (Inconel) or superior chemical resistance (Hastelloy).

Choosing the Right Material:

- Indoor applications with mild environments: AISI 304 (SS304) is a cost-effective and versatile choice.

- Outdoor applications, marine environments, or high humidity: AISI 316 (SS316) provides superior corrosion resistance.

- Welded mesh projects: AISI 304L (SS304L) or AISI 316L (SS316L) are preferred due to their improved weldability.

- High-temperature or harsh chemical environments: Explore special alloys like Inconel or Hastelloy for optimal performance.

What is Stainless Steel?

With the addition of 11% or more chromium to steel, the alloy becomes non-staining under most conditions that corrode plain steel, thus the term stainless is applied.

Major SS Types and Properties:

Type 304 Wire Mesh:

Often referred to as "18-8" (18% chromium, 8% nickel) T-304 is the basic stainless alloy most commonly utilized for wire cloth weaving. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 1400 Degrees Fahrenheit.

Typical 304 stainless wire cloth applications include use with chemicals, food products, pharmaceuticals and exposure to moisture.

Type 304 L Wire Mesh:

Type 304 L is very similar to T-304, the difference being the reduced carbon content for better weaving and secondary welding characteristics.

Type 309

A heat resistant alloy (23% chromium, 12% nickel) which is useful in temperatures up to 1700 Degrees Fahrenheit.

Type 310

Retains good strength and toughness at high temperatures and may be used to advantage where a combination of strength, toughness and oxidation resistance is essential. Where reducing or carburizing conditions are encountered at high temperatures, T-310 is preferred.

Type 310 has a coefficient of expansion slightly lower than most other chromium - nickel alloys.

Type 316

Stabilized by the addition of 2% molydbenum, T-316 is an "18-8" alloy.

Type 316 has better resistance to pitting corrosion than the other chromium-nickel stainless steels where brines, sulphur-bearing water or halogen salts, such as chlorides are present. A valuable property of T-316 is high creep strength at elevated temperatures. Other mechanical properties and fabricating characteristics are similar to T-304.

Stainless Steel Wire cloth woven of T-316 has extensive use in chemical processing when better corrosion resistance is required than the regular chromium-nickel types.

Type 316 L

Type 316 L is very similar to T-316, the difference being the reduced carbon content for better wire cloth weaving and secondary welding characteristics.

Chemical Composition Comparison List of Stainless Steel Wire Material 304, 304L, 316, 316L, 430 and 430L

| AISI Grade |

Chemical Composition(%) | |||||||

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

| 304 | =<0.08 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 8.00 ~ 10.50 | 18.00 ~ 20.00 | - |

| 304H | >0.08 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 8.00 ~ 10.50 | 18.00 ~ 20.00 | - |

| 304L | =<0.030 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 9.00 ~ 13.50 | 18.00 ~ 20.00 | - |

| 316 | =<0.045 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 10.00 ~ 14.00 | 10.00 ~ 18.00 | 2.00 ~ 3.00 |

| 316L | =<0.030 | =<1.00 | =<2.00 | =<0.045 | =<0.030 | 12.00 ~ 15.00 | 16.00 ~ 18.00 | 2.00 ~ 3.00 |

| 430 | =<0.12 | =<0.75 | =<1.00 | =<0.040 | =<0.030 | =<0.60 | 16.00 ~ 18.00 | - |

| 430A | =<0.06 | =<0.50 | =<0.50 | =<0.030 | =<0.50 | =<0.25 | 14.00 ~ 17.00 | - |

304 Mechanical properties:

| Material | SUS304 |

| tensile strength(Mpa) | 520 |

| yield strength (Mpa) | 205-210 |

| Elongation(%) | 40% |

| Hardness | HB 187 ,HRB 90,HV200 |

| Density(g/cm³ ) | 7.93 |

| melting point | 1398-1420 |

| Cr(%) | 17.00-19.00 |

| Ni(%) | 8.00-10.00 |