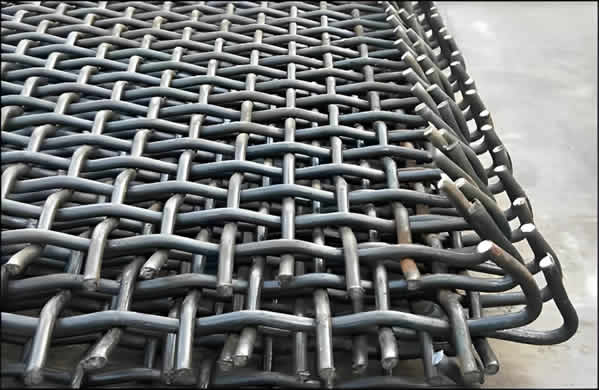

Vibrating Screen is a specialized wire mesh screen in industrial processes for sorting, grading, or sieving powders, granules, liquids, and solids. Vibrating screen cloth is used to separate particles by using vibration to agitate the material, causing it to pass through the screen mesh. Vibrating sifting mesh can effectively remove impurities and ensure consistent particle sizes in mining ore separation, coal screening, sifting, scalping and sizing. Vibrating screen is a high tensile woven wire screen also known as Vibratory Scalping Screen, vibrating screen cloth, mining screen mesh, sifting mesh.

Features:

Durable and efficient wire mesh screens;

Robust construction;

High tensile strength;

Precision in separating materials by size;

Abrasion resistance for tough materials.

Applications:

Heavy duty woven wire mesh vibrating screen is commonly used in mining, metallurgy, construction and recycling industries.

Weave Options:

- Double Crimp Weave (Common): For sizing and scalping applications.

- Flat Top: Minimized friction, extended screen life, for scalping and demanding tasks.

- Inter Crimp Weave (Lighter Duty): Provides a larger open area for less abrasive materials.

- Rectangular Slot (High Moisture): Screens materials for high moisture content.

- Long Slot (Damp Material): Suitable for dedusting and screening damp materials.

Double Crimp

Flat Top

InterCrimp

Rectangular Slot

Long Slot

Edge Options:

- Cut Edges: Simple & Cost-Effective

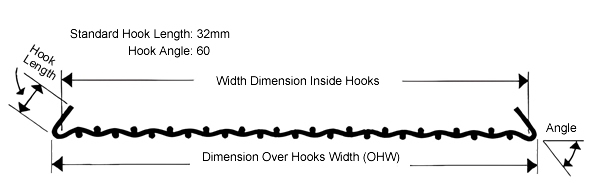

- Plain Hooks (Secure Fit): For medium to heavy-duty applications, these hooks latch onto the screen frame for a secure fit. (Generally for wire diameter 8.0mm or above).

- Sheathed Hooks (Enhanced Durability): Similar to plain hooks, with an added protective sheath for high abrasion resistance. (Generally for wire diameter 7.1mm or below).

Sheathed Hooks

Plain Hooks

Cut Edges

Ordering Information:

- Specify the edge type (cut edges, plain hooks, or sheathed hooks) or provide a drawing for custom requirements.

- Indicate aperture (mesh size), wire diameter, weave pattern, and material.

- Provide screencloth length and width. If hooks are needed, specify the O.H.W. (Over Hooks Width) dimension.

Available:

- Fine mesh (2-1000 mesh) in galvanized and SS304

- Perforated metal (hole size 1-25 mm) in galvanized and mild steel

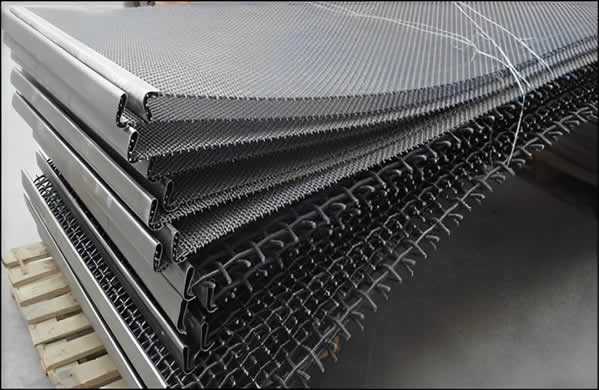

Hook Edged Vibrating Screen

The edge construction is critical for proper installation and screen life. We recommend vibrating screen cloth with hooked edge:

Flat-Top High Tensile Steel Woven Wire Screen Specifications

- Material: High Tensile Steel (High Carbon 0.64-0.71%)

- Standard: GB699-88 NO: 60-65 MINIMUM

- Aperture Accuracy: Aperture must be within ±5%. For example, if the specified aperture is 10.00 mm, the final aperture after weaving should be within a minimum of 9.5 mm and a maximum of 10.50 mm.

- Weave Type: Flat-Top Weave

- Edges: Hooked Edges

- OHW Clarification: OHW stands for “Overall Hook Width”. It refers to the total width of the screen panel, including the width of the opening (aperture) and the diameter of the wires on both sides, but not accounting for the hooked edges themselves. The hooked edges are for securing the screen, and their width might vary slightly depending on the manufacturer. Therefore, OHW provides a more consistent measurement for the screen itself.

Screen Sizes and Specifications:

| Type | Width (OHW) | Width (OHW) | Aperture | Wire Diameter | Quantity |

| A | 1219 mm | 2410 mm | 25.4 mm | 7.1 mm | 200 pieces |

| B | 1372 mm | 2082 mm | 9.5 mm | 4.0 mm | 80 pieces |

| C | 1232 mm | 2057 mm | 44.50 mm | 11.2 mm | 100 pieces |

We can help select the appropriate weave, material, and edge type, and providing detailed specifications, and deliver quality high tensile wire mesh screen cloths for your specific application.