410 wire mesh is made of high-grade martensitic stainless steel with 11.5-13.5% chromium and minimal nickel content. 410 grade stainless steel wire mesh features high tensile strength, wear resistance and structural integrity at elevated temperatures.

Application: 410 stainless steel wire mesh is used mainly in petrochemical, automotive, aerospace, and food processing for filtration, screening and other applications.

410 Stainless Steel Wire Mesh Standards:

- T-410 Wire Mesh

- SS 410 Wire Mesh

- UNS S41000 Wire Mesh

- SUS 410 Wire Mesh: Specific standard (SUS) used in Japan for classifying this stainless steel type (410).

- DIN 1.4006 Wire Mesh: German standard system code (DIN 1.4006) for 410 stainless steel.

- 410 Stainless Steel Cloth

- 410 Stainless Steel Screen: Used to separate or filter materials through a screening process.

410 Stainless Steel Wire Mesh Specifications

- Material: Martensitic stainless steel (grade 410) for strength and corrosion resistance.

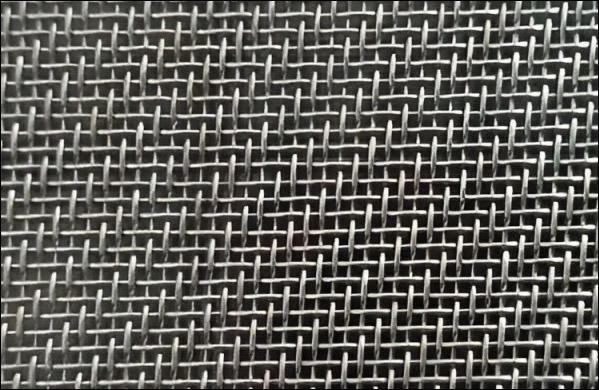

- Mesh Count: 1 to 635 openings per linear inch (0.4 to 250 openings per cm).

- Wire Diameter: 0.001″ to 0.12″ (0.0254 mm to 3.048 mm).

- Micron Rating: 25 to 6000 microns (particle size filtration).

- Standard Widths: 24″, 36″, 48″ (610 mm, 915 mm, 1220 mm).

- Open Area: 30% to 80% (depending on mesh count and wire diameter).

- Shapes: Rolls, sheets, discs, and custom cut sizes.

- Operating Temperature: -100°F to 1200°F (-73.3°C to 649°C).

- Filtration Ratings: Coarse to ultra-fine (based on particle removal efficiency).

- Roll Length: 100 ft (30.48 m) standard with ±0.5% tolerance.

- Roll Width Tolerance: ±0.125″ (±3.175 mm) for standard widths (custom widths available).

- Standards: ASTM E2016 and others.

- Finishing: Passivation, cleaning, and annealing options for improved performance.

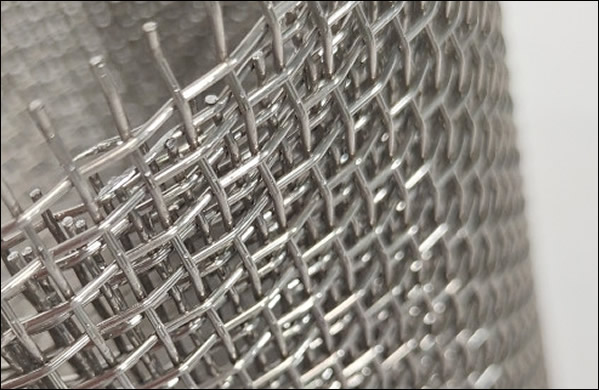

- Weave Types: Plain, twill, and Dutch weave (each with specific filtration and strength).

- Construction: Woven or welded mesh for various application needs.

- Packaging: Rolls or sheets, protected by plastic wrap in wooden crates.

- Customization: Customizable packaging options available.

Sizes of 410 Stainless Steel Woven Wire Mesh

| Mesh Count (Per Inch) | Wire Diameter (mm) | Aperture/Opening (mm) |

| 2 | 1.600 | 10.70 |

| 4 | 1.200 | 5.35 |

| 8 | 0.810 | 2.35 |

| 16 | 0.457 | 1.11 |

| 24 | 0.355 | 0.76 |

| 30 | 0.305 | 0.55 |

| 40 | 0.223 | 0.39 |

| 50 | 0.182 | 0.32 |

| 60 | 0.152 | 0.27 |

| 80 | 0.122 | 0.20 |

| 100 | 0.102 | 0.15 |

| 120 | 0.081 | 0.13 |

| 150 | 0.061 | 0.11 |

| 180 | 0.053 | 0.09 |

| 200 | 0.053 | 0.08 |

| 250 | 0.041 | 0.05 |

| 300 | 0.033 | 0.03 |

| 325 | 0.030 | 0.02 |

| 400 | 0.025 | 0.02 |

| 500 | 0.020 | 0.01 |

| 635 | 0.016 | 0.01 |

Physical Properties of SS 410 Twill Weave Wire Mesh

Material Composition:

- Type: 410 Stainless Steel

- Chromium Content: 11.5-13.5%

- Nickel Content: Minimal to none

Mesh Characteristics:

- Mesh Count: Typically ranges from 1 to 100 openings per inch.

- Wire Diameter: Ranges from 0.001 inch (0.0254 mm) to 0.12 inch (3.048 mm).

- Aperture/Opening: Size varies from 25 microns to 600 microns, depending on mesh count and wire diameter.

Mechanical Properties:

- Density: 7.75 g/cm³

- Tensile Strength: Approximately 520-770 MPa

- Yield Strength: Approximately 275 MPa

- Elongation: 20-25% in 2 inches (50.8 mm)

- Hardness: Rockwell HRB 88-96

Environmental Properties:

- Operating Temperature: Effective from -100°F to 1200°F (-73.3°C to 649°C)

- Corrosion Resistance: Good, particularly enhanced with passivation treatments.

Magnetic Properties:

- Magnetic

Open Area:

- Percentage typically ranges from 30% to 80%, depending on mesh count and wire diameter.

Standard Roll Dimensions:

- Length: 100 feet (30.5 meters)

Width: Common options include 24 inches (610 mm), 36 inches (915 mm), and 48 inches (1220 mm).

Customization:

- Custom widths, lengths, shapes, and additional treatments (passivation, cleaning, annealing) are available to meet specific requirements.