Weaving

Major weaving patterns of our woven wire mesh cloths, introduced with weaving process, advantages of each pattern and suitable applications, for customers reference to choose the suitable product for your specific requirements.

Home » Weaving Types

Woven Wire Mesh Weaving Types

Woven wire mesh is manufactured in a variety of weaving types to suit different applications and requirements. Here are the most common weaving types:

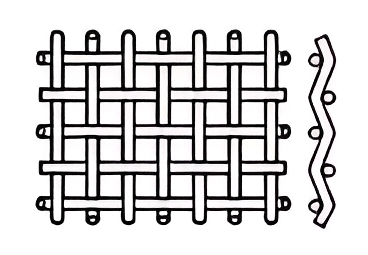

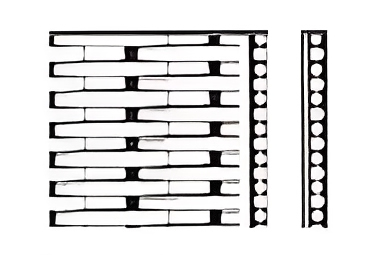

1. Plain Weave

Description: The simplest and most commonly used weave. Each warp wire crosses alternately over and under each weft wire.

Applications:

General filtration, industrial sieving and protective barriers.

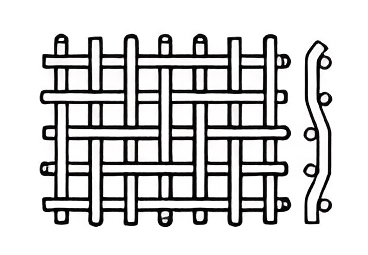

2. Twill Weave

Description: Each warp wire passes over two and under two weft wires. This pattern creates a diagonal appearance and allows for higher density mesh.

Advantages: Stronger than plain weave. Handles heavier loads.

Applications: Fine filtration and high-pressure filtration.

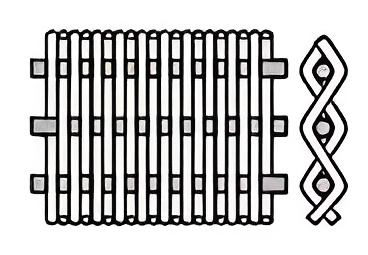

3. Dutch Weave

Description: The weft wires are thicker and closer together than the warp wires, resulting in a very fine filtration mesh.

Types:

Plain Dutch Weave: Combines plain weave with a higher density of weft wires.

Twill Dutch Weave: Combines twill weave with closely spaced weft wires for finer filtration.

Applications: Fine filtration for liquids and gases and hydraulic filters.

4. Dutch Twill Weave

Description: The Dutch Twill weave features an intricate pattern where the warp wires pass over and under multiple weft wires in a diagonal fashion, creating a distinctive twill appearance.

Applications: Fine filtration in chemical and food industries. High-performance sieving and screening in industrial processes.

5. Reverse Dutch Weave

Description: The warp wires are thicker than the weft wires, creating a strong and dense mesh with excellent filtration properties.

Applications:

Used in applications requiring reverse flow filtration.

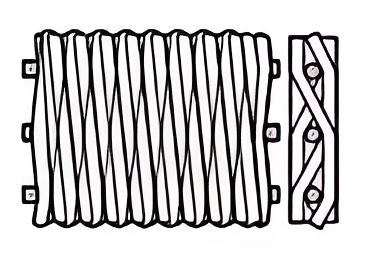

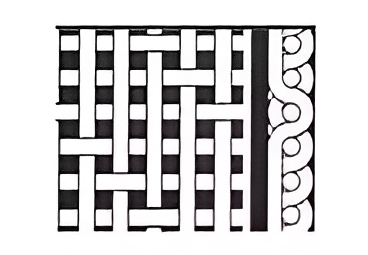

6. Five-Heddle Weave

Description: Each warp wire alternates between crossing over and under five weft wires. A flat, smooth surface with better drainage and flow.

Applications:

Paper and pulp industries, also architectural applications.